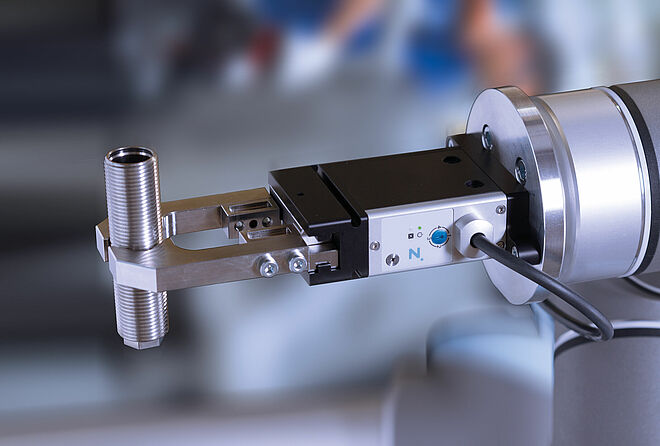

Een compacte automatisering is een mechatronisch systeem dat een complete reeks achtereenvolgende productiestappen zelfstandig uitvoert. Bij "compact" gaat het hierbij om de producten die moeten worden verwerkt, met afmetingen van enkele centimeters of zelfs millimeters. Het ontwerpen...